OIL & GAS PROCESSING

SOLUTIONS

TAJS Energy delivers engineered, skid-mounted process packages and lifecycle field services that enhance uptime, safety, and compliance across upstream, midstream, and downstream operations. Our Solutions span separation, gas treatment, heating, filtration, nitrogen, and pressure control, with integrated design, fabrication, and commissioning support for rapid deployment and reliable performance in harsh environments.

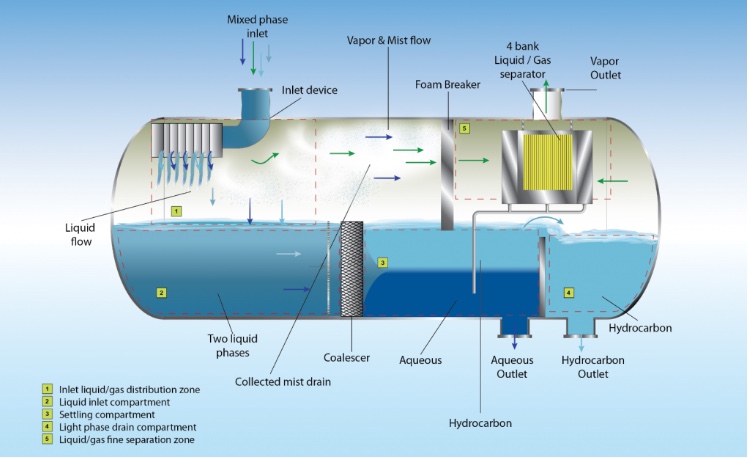

TAJS Energy deploys advanced two-, three-, and four-phase separators engineered to deliver precise oil, gas, water, and solids management—optimizing production performance and test operations in even the most demanding field environments.

Heater treaters and metering packages are integrated to minimize bulk solids and ensure custody transfer accuracy.

Engineering and features

- Internals selection (inlet diffusers, coalescers, mist extractors) tailored to fluid properties and turndown range.

- ASME-coded vessels, process controls, and safety interlocks are packaged on transportable skids

Outcomes

- Optimized separation efficiency, lower carryover, and improved downstream reliability.

- Reduced emissions and flaring via stable gas-liquid management and level control.

Purpose and scope

- Removal of liquids and solids to achieve turbine/engine fuel gas cleanliness, pressure, and temperature specifications.

- Conditioning for gas sources, including GDUs and sales gas pipelines, to protect combustors and meet emissions goals.

System building blocks

- Filtration/coalescing stages, heaters/chillers as needed, pressure control, and condensate handling.

- Integrated control loops to maintain setpoints under variable flow and composition.

Benefits

- Extended downstream equipment life, stable combustion, and compliance with environmental standards.

- Reduced unplanned shutdowns and smoother startup ramp profiles for turbines.

Indirect Water

Bath Heaters

Operating principle

- Indirect heating using a water or water-glycol bath, with process coils immersed to ensure uniform heat transfer without high-pressure containment.

- An external burner-driven bath reduces hot spots and the risk of carbon buildup in the process stream.

Design attributes

- Skid-mounted assemblies with burner management systems, temperature control, and safety interlocks.

- Configurable for preheat, dew point control, and upstream pressure letdown protection.

Value delivered

- Reliable gas heating across changing ambient and flow conditions with reduced thermal stress on piping and equipment.

- Enhanced safety and maintainability via accessible coil and instrumentation layout.

Fired Heaters

Use cases

- Process heating for oil and gas service where direct-fired duty or custom thermal profiles are required.

- Integration with upstream/downstream skids for compact footprints and simplified controls.

Features

- Combustion controls, flame safeguard systems, and emissions-conscious burner selections.

- Fabrication to applicable codes with performance testing prior to shipment.

Outcomes

- High thermal efficiency and stable duty under turndown while maintaining safety margins.

- Reduced commissioning time via packaged designs and documented control logic.

Molecular Sieve

Dehydration

Purpose

- Deep gas dehydration for stringent water content limits, protecting cryogenic and pipeline systems.

- Suitable for feed gas with variable H2O loading and tight dew point requirements.

Package design

- Twin or multiple beds with automated switching, regeneration heaters, and off-gas handling.

- Instrumented sequences to protect sieve life and ensure consistent outlet specifications.

Benefits

- Extended adsorbent life through optimized cycles and temperature control.

- Assured downstream integrity and elimination of hydrate formation risks.

Gas Dehydration

Systems

Scope

- TEG and other contactor-based systems for bulk gas dehydration to pipeline or plant specifications.

- Designed for field variability, seasonal swings, and operator-friendly maintenance.

Key elements

- Contactor towers, regeneration units, reflux/flash control, and mist elimination.

- Controls and safeguards for circulation rates, temperatures, and hydrocarbon management.

Performance

- Reliable outlet water content with energy-efficient regeneration.

- Reduced foaming and carryover via internals selection and process tuning.

Gas Filtration

Mission

- Removal of particulates and liquid aerosols to protect compressors, meters, exchangers, and catalytic units.

- Applicable from the wellhead through transmission to plant inlets.

System options

- Cartridge, coalescing, and dual-stage designs with differential pressure monitoring.

- Drain systems for condensate management and environmental compliance.

Benefits

- Improved equipment reliability and longer service intervals.

- Consistent gas quality supports accurate metering and efficient combustion.

Nitrogen

Generation

Applications

- On-site nitrogen for purging, blanketing, pressure testing, and maintenance operations.

- Deployed in upstream wellsites, midstream stations, and processing plants.

Package features

- Skid-based PSA or membrane systems with air pretreatment and purity controls.

- Integrated safety and monitoring for continuous, autonomous operation.

Outcomes

- Reduced dependency on delivered N2 and improved operational flexibility.

- Lower total cost over the lifecycle with rapid availability and scaled capacity.

Pressure Reducing

Stations

Role

- Safe, precise pressure control for gas and fluids across pipelines, metering stations, and process units.

- Applicable to steam, utilities, and wellhead letdown on offshore and onshore assets.

Engineering highlights

- Redundancy, overpressure protection, and materials specified to service conditions.

- Tailored pressure ranges and flows with lifecycle technical support.

Benefits

- Protection of downstream assets and consistent process stability.

- Reliable performance in harsh environments with maintainable, modular layouts.

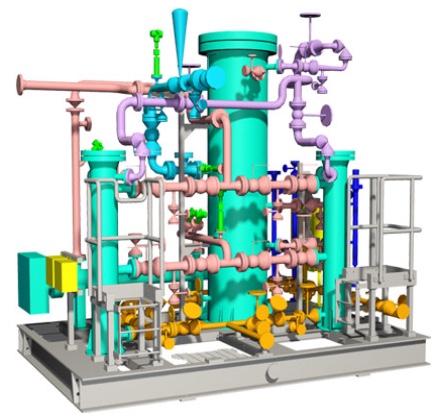

Integrated Packages and Support

- Modular wellsite and processing skids

- End-to-end design, fabrication, testing, and packaging for rapid mobilization and minimal site work.

- Harmonized controls across separation, heating, dehydration, and filtration for unified operations.

Field services

- Installation, commissioning, operator training, and maintenance programs to accelerate time to value

- Rental, repair, and LSTK execution models to match project needs and budgeting.

WHY TAJS ENERGY

What sets us Apart

Proven modularization:

Faster projects, smaller footprints, less site risk.

Controls harmonization:

Unified HMI and logic across packages for simpler operations.

Lifecycle support:

Commissioning, training, spares, and performance tuning that keep assets on‑stream.